Feasibility studies

Passion and collaboration drive our daily dialogue with designers, builders, engineered wood producers, and building system manufacturers and installers. This continuous exchange—from design excellence to hands-on execution—enhances our creativity and refines our working methods.With extensive experience in successful projects across Italy and abroad, we’ve learned to anticipate challenges, implement quality controls, and optimize logistics and operations. This allows us to deliver sustainable technical solutions, even for complex designs.

As specialists, we know that building high-quality structures within budget requires more than regulations, advanced software, and calculations—it demands hands-on experience.

Working with wood means understanding its strengths and limitations, its journey from forest to classified structural element, and its structural behavior. This expertise helps us optimize design and production, streamline transportation, and ensure fast, safe on-site execution.

01 Preliminary design

Before starting our preliminary design there is always a collaborative approach to the project. We meet designers, clients and builders, with the aim of sharing a common vision aimed at preventing waste of time, industrialising production and prefabrication, and optimising costs. Preliminary design allows us to verify the technical solutions suitable for the feasibility of the architectural project, to define the structural elements and to assess, together with the designer, their dimensional and aesthetic impact, in order to harmonise architecture with engineering.

02 Working design

Working structural design and 3d seismic implementation of the structure, allow to define the size of the connections according to stresses, sections, CNC woodworking of structural elements as well as every other technological detail. The working project defines all dimensions useful for the realization of complementary works. This design is submitted for approval by the designer appointed by our client, before production start.

03 Manufacturing design

To start procurement of wooden structures and steel connections, manufacturing plants receive bills of quantity and shop drawings to produce materials upon the work schedule we fix in advance.

Each wooden element and steel joint is numbered and graphically represented in detail. All woodworking operations, even the most complex ones, are translated into CNC file format that the CNC machines can easily understand.

04 Completed work

The end of the works onsite is the conclusion of a journey that the client experiences with us from feasibility study to design, from production to construction. Visits and surveys on site before the arrival of the materials, coordination of deliveries and installers, assistance and presence during the works, are essential services for the good realization of the work which we were assigned by the client.

Research & Development

Over the years, curiosity together with passion have continually pushed us to look for new materials, new solutions and new systems in order to improve our constructions and raise quality and safety standards. Wood is always able to surprise and amaze us, feeding our passion. We take part in trade exhibitions, seminars and international forums, we talk with the most technologically advanced manufacturers, we focus our attention on ingenious artisan, on exclusive, high-performance, eco-sustainable material.We design, we experiment, we develop our ideas together with experts and universities.We move on without stopping.

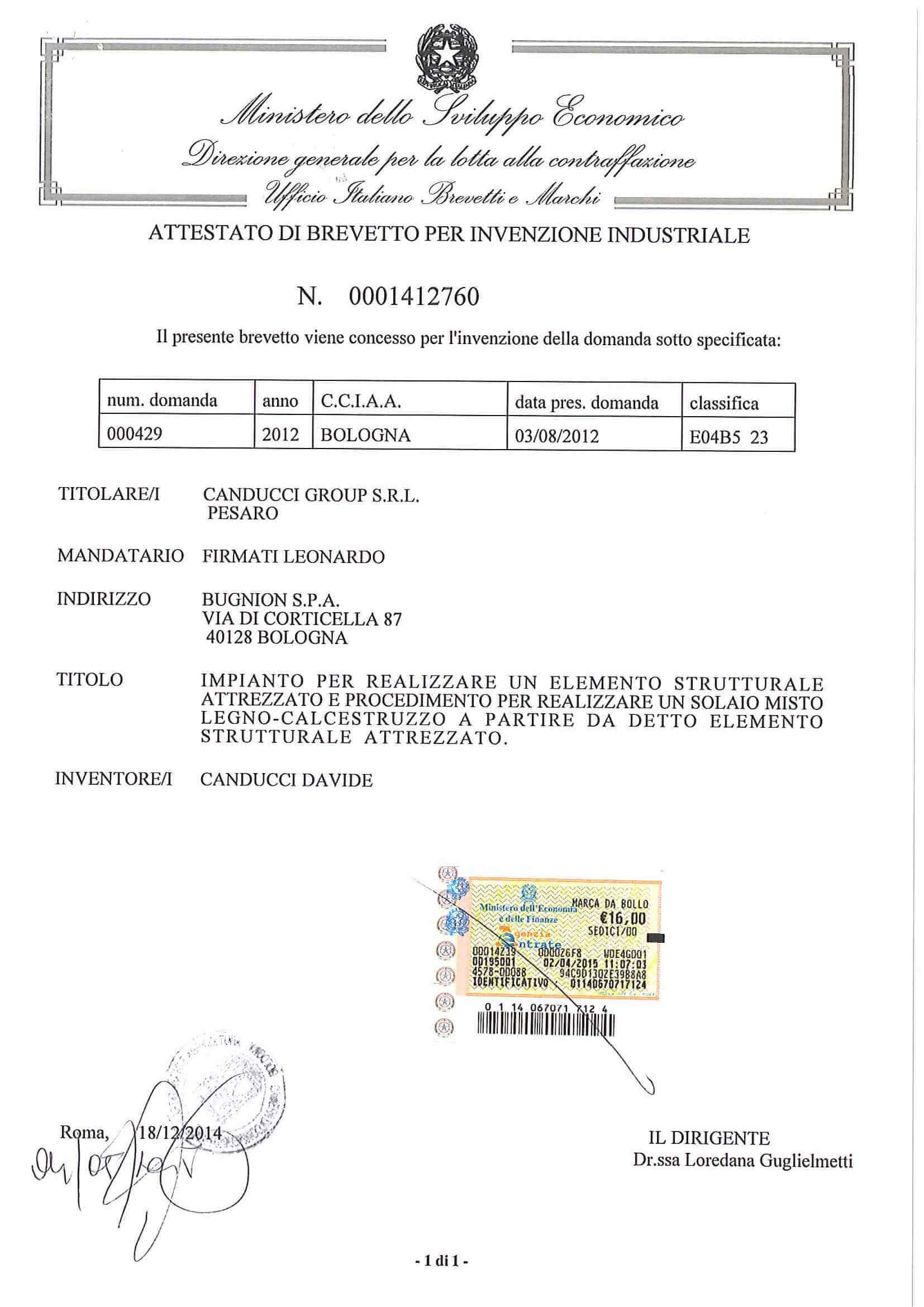

Soluniko®

It is an innovative and patented system which can be used to realize high-performance composite timber-concrete floors. It is ideal both for renovation and for new buildings.Glulam beams leave the factory equipped with special steel connectors and side seals.

This stage follows strict production protocols, so that they arrive onsite ready to be installed.

They are functional, safe in use and quick to build.

Each connector is composed by four structural steel elements which are studied and certified to guarantee the highest flexibility according to the features of each project: span, interaxle spacing, loads.

The close relationship between timber and concrete guarantees high performances, structural safety, technological reliability.

System tested and certified

System tested and certifiedConnectors at stadardized distance

Quick and easy to build

Tailor made and ready to install

High Anti-seismic performance

Sound comfort

Experimental laboratory tests of Soluniko registered a breaking value among the highest ever recorded in scientific literature as well as high stiffness. DOWNLOAD DOCUMENTATION

DOWNLOAD CATALOG